Quality Plastic Injection Molding Services

With a lot of plastic injection molding engineering support

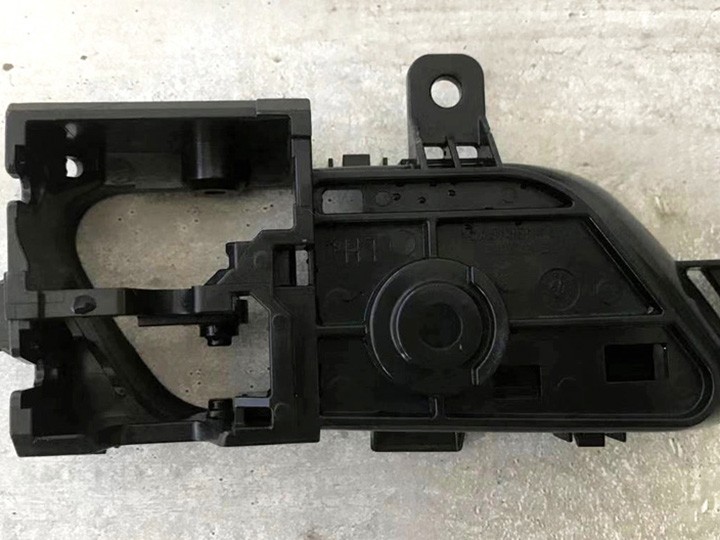

Custom Plastic Injection Molding Services

Three common injection molding services we deliver on for custom plastic injection molded parts:

Export Injection Molds (bridge part production) – we are making a custom injection mold for you and shipping to your facility so that you can do your own injection moided parts. But, you also need X amount of production parts shipped with your injection mold. This is often referred to as ‘bridge’ production.

Rapid Tooling (low volume part production) – we are making a mold for you fast so you can get X amount of production quality injection molded parts fast. We can store your rapid tool at our factory (so that it is ready for your next order), or ship your rapid tool to you with your parts. Our P20 rapid tools are a great ROI, delivering a lot more injection molded parts than you are used to getting when compared to USA and EU rapid tooling programs.

Turnkey Injection Molding (medium to high volume part production) – we make the injection mold for you, we make the parts for you and store your mold at our facility, ready for your future plastic part production needs. A turnkey plastic part injection molding solution.

We make injection molded parts using two-plate injection molds, three plate injection molds, stack injection molds, family injection molds, overmolds, insert molds, rapid tooling molds, and more. We have 29 in-house injection molding presses from 50 T to 1100 T that gives us the capacity to service a wide range of injection molded plastic parts projects simultaneously. Get in touch If you need some guidance on what injection molding program is right for your project.

Offshore Injection Molded Parts - Pricing That Works

- Injection Mold Making: Export injection molds & in-house mold solutions

- Injection Molded Parts: High quality plastic parts (low to high volumes)

- Great Plastic Part Price: Globally competitive injection mold & part pricing

- Bonus Savings: Uniquely save on mold and part tariffs (USA customers)

- Engineering: Massive engineering support on your plastic part design

- Experience: Injection mold and part production solutions since 2006

- Communication: Native English for engineering & project management

- Factory: 59,000 sq ft ISO 9001:2015 factory for mold making & parts

- Quality: USA quality approach to part quality via our custom QC App

- Trust: All paperwork through Jade Group INTL, a USA company

BONUS: Unique savings of up to 50% OFF your USA plastic injection mold & parts tariffs.

Injection Molding Materials

Choosing the right material for your part is of vital important to the overall success of your project. If you choose a material that is over engineered for your needs then the part costs may be too much for your project. On the other hand, choosing the wrong material because it is the cheaper option can also hurt your project goals and part performance.

Our team can help guide you through the material selection process to help ensure you get a fit for purpose material at a price point that makes sense for your overall project needs..

Surface Finishing & Secondary Processes

We make molds for export and domestic production runs for just about every industry. With that comes the need to be able to apply a wide range of surface finishes.

From a low cosmetic finish to a high mirror polish to bead blast, etching, matte finish, we can deliver whatever surface finish your part needs.

If your injection molded part requires a secondary finishing process like pad printing, silk-screening, assembly or other requirement we can help guide you to the best option and deliver on that option.

How can we help you?

- Looking for an injection mold making quote?

- Need a project review of an existing design you have?

- Have questions about how mold making in China works?

- Looking for A La Carte engineering or Moldex3D services?