Injection Mold Tooling | Great Prices | Massive Engineering Support

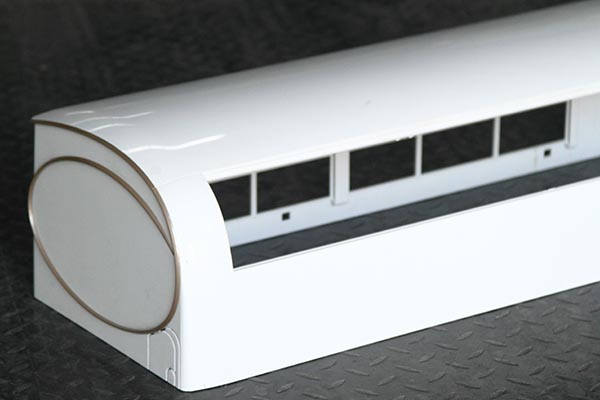

- General Purpose Molds

- High Production Molds

- Hot Runner Specialists

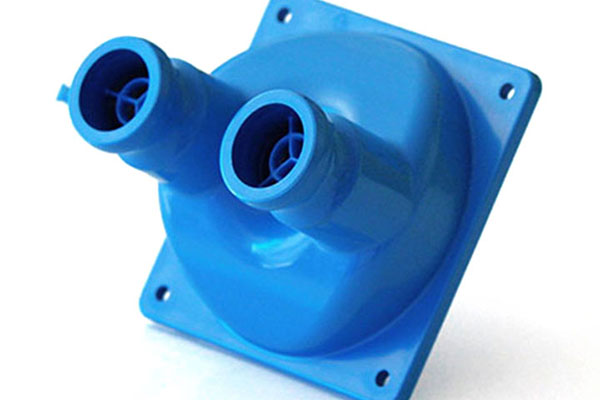

- Caps & Closure Molds

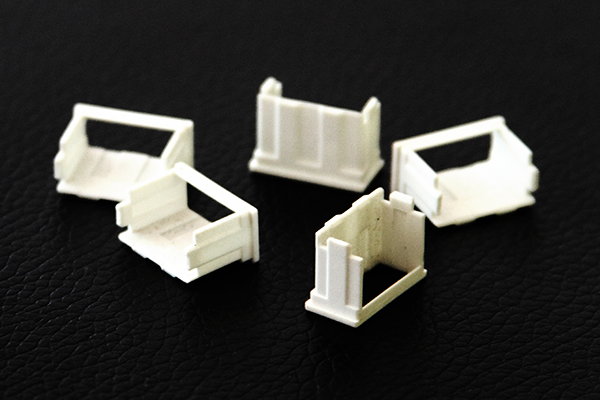

- Rapid Tooling

- Automotive Molds

- Unscrewing Molds

- Thermoset Molds

- Pet Treat Molds

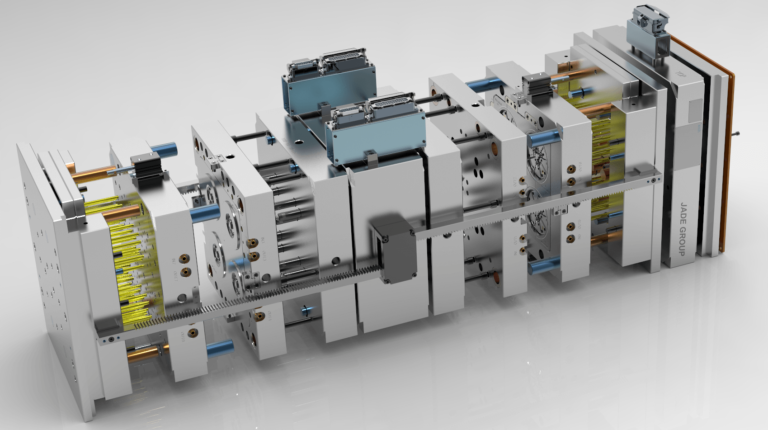

- Stack Molds

- Family Molds

- Insert Molds

- Overmolds

- Mold Bases

- 2K molds

Injection mold tooling advantages you get:

- Great injection mold pricing that helps to keep you globally competitive

- Plus, with Jade you can uniquely save up to 50% OFF your injection mold tariffs

- Massive injection mold engineering support that highly qualifies your project

- Enhanced injection mold DFM with Moldex3D included on all mold projects

- USA approach to offshore injection mold making and project management

- Custom QC App for better live data capture and faster issue resolution (if any)

- Crystal clear communication on your injection mold project via Native English PMs

- You save via mold price, engineering support, DDP shipping/tariffs, and travel

- All paperwork is with Jade Molds USA based company, no international wires

Our injection mold pricing will help you win more injection mold part production projects.

The single biggest factor that prevents injection mold makers from winning more injection molded part production jobs is part price and the single biggest factor in determining part price is the cost of the injection mold tool. We will not only deliver you a great injection mold tooling price but also a USA approach (Enhanced DFM, Mold Design, Project Management, Injection Mold Making, Quality Control, Communication) to offshore injection mold making.

With communication always in native English we are able to a smooth offshore injection mold making experience and offer an advantage when it comes to ECN requests. The results are injection molds that run great in your presses back home and meet your highly specific injection molding production goals. How can we help you? Get in touch.

BONUS: Unique savings of up to 50% OFF your USA plastic injection mold & part tariffs.

Some of the offshore custom injection mold tooling services we offer:

Injection Mold Bases: What are your options for building Injection Mold Bases? Buy blanks from mold base suppliers and build your mold base in-house (inefficient and a bit expensive). Buy completely machined custom injection mold bases from domestic mold base suppliers (efficient and expensive). Or buy completely machined custom injection mold bases from offshore mold base suppliers (efficient and inexpensive).

Why do you have your highly skilled mold builders making your mold bases in house when you can buy off shelf at a great price that keeps you globally competitive? Talk to our team.

How can we help you?

- Looking for an injection mold making quote?

- Need a project review of an existing design you have?

- Have questions about how mold making in China works?

- Looking for A La Carte engineering or Moldex3D services?

Tips for qualifying Injection Mold Tooling Suppliers

- Test your supplier on communication skills. They are likely not as good as your first impression. Learn how...

- Qualifying suppliers via factory audits is crucial and it can be very hard to know what is true. Learn more...

- The injection molding process in the West is not the same as in China, you need to understand this point. Learn more...

- There are a lot of false claims made by China suppliers during high tariff times. Be careful. Learn more...

- Ask your supplier if they are using advanced engineering tools like Moldex3D for mold design. Learn more about Moldex3D...

- Factory location matters and working with a supplier you can trust remotely during COVID-19 is vital. Learn more...

- A great price is exciting but you need to qualify that price properly. Here is a bit of fun on a serious topic, check it out...

- To ask a question or start a quote click here to get in touch with our Western mold building team in China.