USA Approach To Design & Quality Control

- Enhanced DFM + Moldex3D highly qualifies your part design and mold design

- Your mold is designed to USA standards, all updates by USA engineers & PMs

- Highly tracked projects via our custom injection mold project management system

- Quality control data capture & QC reports via our custom injection mold QC App

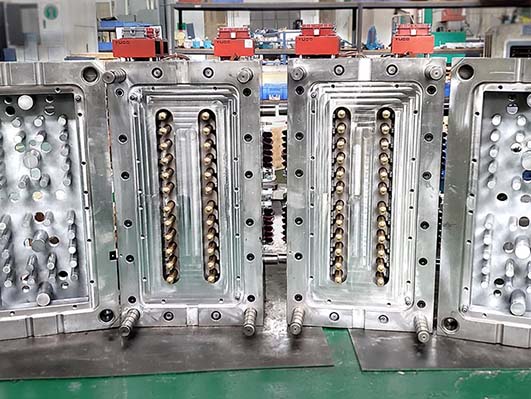

- Jade built injection molds deliver you a better China manufacturing experience

Injection Mold Quality Process

By leveraging custom digital quality control and project management solutions our engineering and factory teams can focus more on the details of your project. Resulting in a better injection mold to you.

Quality Control: Custom PM System + Custom QC App

• Automatic email reminders to customers when engineering feedback is late or stalled

• Clear & quick internal communication with automatic email reminders to Jade team members

• Our QC App delivers easy factory data capture, resulting in fast issue follow up and resolution

• QC reports from the App are automatically emailed to our team or customers as appropriate

• Trial Reports + Incoming & Final Steel Hardness Certs + T1 & Final Mold Tear Down Reports

View Sample Report: we only create this report when needed. Very often after T1, but might not be needed after T2.

View Sample Report: we check incoming hardness against the approved DFM and send to you.

View Sample Report: this is a simple double check to ensure steel hardness before your mold ships

View Sample Report: we completely tear down your mold to identify any and all issues. If issues we still send you the report and work on fixing any issue quickly in preparation for you approving mold shipment.

How can we help you?

- Looking for an injection mold making quote?

- Need a project review of an existing design you have?

- Have questions about how mold making in China works?

- Looking for A La Carte engineering or Moldex3D services?

Jade Outside QC Mold Inspection Services

Helping you in China with outside QC services at your existing supplier might be representing your interests during a mold trial, or troubleshooting a mold build that has gone off the rails, or rescuing a mold where we bring it back to Jade to fix and take over the project.

Westerners on the ground in China is how we fix your mold build problems, with clear native English communication with you that helps to solve the problem quicker without limiting the options available to you. If you are having any problems with a mold builder in China, get in touch today for a free QC consult – [email protected]

Jade Outside QC Production Services

Western Quality Injection mold building and injection mold production are the core services we offer but we are also experienced in rapid prototyping as well as product development. With that our Western QC team is routinely called upon to help QC a variety of part production and product assembly outside of Jade.

There is a big cost associated to flying overseas to QC a product run and the risk of not flying over to verify your product quality can come with dire consequences down the line.

Mitigate your risk and strike a good financial balance with Jade’s QC services. Veteran Western manufacturers on the ground is how we do it. Get in touch today for a free project QC consult.